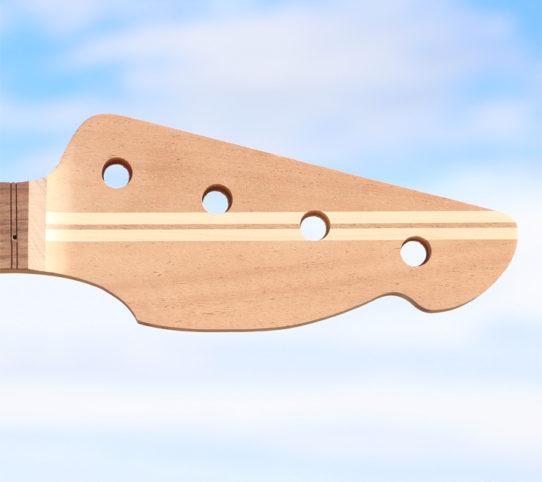

Welcome to part 3 of the Bass Guitar Build. Today, I’m working on the relief cut in the headstock. This is where I...

READ MORE

Welcome to part 3 of the Bass Guitar Build. Today, I’m working on the relief cut in the headstock. This is where I...

READ MORE

I have recently started using Cast Iron Pans for cooking. Cast Iron pans have been around for hundreds of years and they...

READ MORE

A few weeks ago, I began building a bass guitar. The first installment was making the body. This week, the project conti...

READ MORE

My bandsaw is a Rikon 10-305. Its a 10″ benchtop saw that overall works pretty well. There’s one thing that ...

READ MORE

Its time to begin a new guitar build. This time its a bass guitar. This build is a commission and not entirely my own or...

READ MORE

One of the advantages to being a woodworker is that you get to make things for others. We all love a nice handmade gift,...

READ MORE

Every time I sit down and begin modeling a part in Fusion 360, I learn new things. I may be a feature of the software th...

READ MORE

If you have a riding lawn mower, its quite possible that you will eventually end up with a flat tire. This can be caused...

READ MORE

Many guitar builders use templates to create their various parts and pieces. These templates are typically made from MDF...

READ MORE

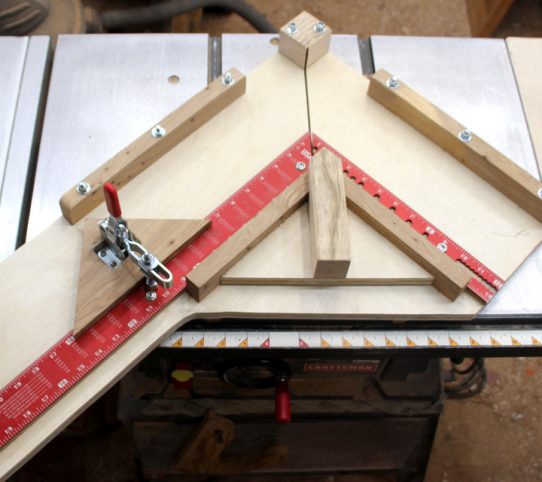

I decided to try to increase the quality and accuracy of my picture frame making by building a dedicated Picture Frame M...

READ MORE

My workshop is very small. From my best estimate, I have about 110 – 120 square feet of space to work in. This is ...

READ MORE

Are the headlights on your vehicle looking faded and hazed over? Mine are, so I decided to try restoring them myself usi...

READ MORE